|

| May 24, 2016 | Volume 12 Issue 20 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Wheels: Carbon-fiber wheels offered on Ford GT supercar

If you're going to lay down $400,000 for a new Ford GT supercar, it's nice to know it comes with options.

One impressive one, although it'll cost you, is carbon-fiber wheels to match the supercar's carbon-fiber exterior, which is pretty cool if that woven-fiber look is your thing when it comes to automotive styling and performance.

Ford GT is the second Ford Performance vehicle to offer carbon-fiber wheels, following the world's first mass-produced carbon-fiber wheel application that debuted as standard equipment on the 2015 Shelby GT350R Mustang.

"Ford was the innovator as the first to offer mass-produced carbon-fiber wheels as a standard offering on Shelby GT350R Mustang," said Dave Pericak, Ford Performance global director. "Now, Ford GT will offer the next generation in carbon fiber wheels, with an advanced resin and fiber technology that gives our designers more freedom, while also showcasing the structure of the material's weave."

Unlike the Shelby GT350R's black-painted carbon fiber wheels, Ford GT wheels will be offered in two finishes: either a matte or a glossy clearcoat, permitting the extra cool look of the carbon fiber weave to show through. The finishes perfectly match the two exposed carbon finishes available on the sills, fascia, and extractor of the all-new supercar.

Working with Australian supplier partner Carbon Revolution, the new wheels are constructed with the latest generation of fiber and resin technology that permits greater design flexibility -- resulting in flowing, more intricate spokes.

Advantages roll in

Carbon-fiber wheels can bring a wealth of advantages over traditional aluminum wheels, including weight savings, improved vehicle dynamics, and ride quality -- making the innovative material the perfect complement for the all-new Ford GT.

Beyond simply reducing overall vehicle weight for improved acceleration, braking, and dynamic performance, carbon fiber's incredibly strong, light nature means a reduction in unsprung weight and rotational inertia, which benefits suspension action, ride quality, and dynamic performance. Carbon fiber's tensile strength, the ability to withstand longitudinal stress, is 13 times stronger than aluminum.

The Ford GT arrives standard with incredibly light, 10-spoke forged aluminum wheels, size 8.5 x 20 in. in the front and 11.5 x 20 in. in the rear. The optional carbon-fiber wheels on the Ford GT are the same size, but are structurally stiffer and save more than 2 lb of unsprung weight per wheel. Compared to the already featherweight standard wheels, this weight savings reduces inertia by a notable 25 percent, according to Ford engineers.

A lighter wheel also requires the suspension to do less work to control the hardware attached to it, and it improves consistent contact with the road surface, improving traction and driver control. Each spinning wheel also acts like a gyroscope, so a lighter wheel can improve steering feel and dynamics because it requires less energy to accelerate or turn the wheels, improving vehicle response. Vehicle efficiency is improved, because less energy is required to get the wheel spinning.

Also, while metal wheels can act like a bell, the dense, inert nature of carbon fiber provides for overall improved performance in terms of noise, vibration, and harshness (NVH) and a quieter ride -- leading to greater comfort and refinement.

Autoblog says the cost of a similar aftermarket set of carbon-fiber wheels from Carbon Revolution running on a Porsche cost around $15,000.

A quick look at development, manufacturing, and testing

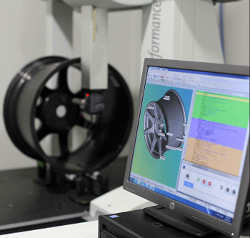

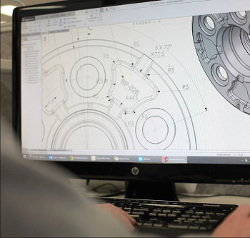

A backgrounder supplied by Ford says that both Ford Performance (the company's aftermarket division) and Carbon Revolution employ virtual product development. Carbon Revolution runs computer models able to simulate wheel durability and stiffness. Manufacturing options can be investigated, as well as analysis of weight and moments of inertia to forecast wheel performance for Ford Performance.

Once the final design concept has been selected, the wheel is optimized through the use of finite element analysis, which is capable of modeling each individual carbon ply and makes it possible to simulate such demanding on-vehicle conditions as hard cornering or driving over a curb, while changing the carbon layup in real time to enable a fully optimized structure for the given wheel design. The ultimate goal is to get the design right the first time to accelerate testing and validation. Testing is done before physical parts are created, which saves time and money because prototyping and tooling are minimized, and the final product performs exactly as engineering intended.

- Manufacturing: Carbon Revolution employs a smart factory with a radio frequency identification quality tracking system. Each wheel is fitted with a radio frequency identification chip, allowing it to be tracked throughout the manufacturing process and service life. This process ensures 100 percent part tracking, identification, and verification of all material batches, processes, operators, processing data, and end-of-line testing.

- Raw material: Carbon Revolution employs a proprietary dry-fiber manufacturing process that allows full control of fiber placement and material properties. It is also using next-generation carbon fiber materials to continue advancing its leading single-piece carbon-fiber wheel technology.

- Fabrication: A proprietary, patented manufacturing process shapes and forms the carbon fiber into the complex internal structure of the wheel. Automated operations result in high-volume, precision fabrication of the carbon-fiber preforms, which are then quality-checked and prepared for resin infusion.

- Infusion: Preformed carbon-fiber components get injected with resin, then a barrage of computer checks and measurements are made using state-of-the-art instruments controlling temperatures, pressures, and hundreds of other processing parameters. The one-piece carbon-fiber wheel is then released for final machining and additional quality checks.

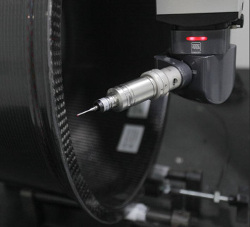

- Quality: Wheels ready for final inspection are put through 181 additional checks and measured at 2,000 data points. Every wheel completes a 3D CT X-ray scan and inspection after it is coated and prepared for shipping to the assembly location for Ford Performance. Every step in the quality process is tracked and logged by the radio frequency identification chip, and is highly repeatable and controllable, ensuring every wheel is set to the high OEM standards of Ford Performance.

- Testing: Carbon Revolution and Ford Performance subject their carbon-fiber composite wheel to the highest testing standards to ensure strength and durability to last the life of the model the wheel is designed for. Testing is focused in three general areas including impact testing, fatigue testing, and vehicle testing.

Impact tests are designed to simulate impacts from potholes and curbs using a calibrated striker to verify the strength of the wheel design and quality of manufacturing. To ensure the one-piece carbon-fiber wheels can go the distance, a bi-axial testing fixture is used for simulating any type of driving conditions to prove out the wheels for hundreds of thousands of miles. While testing in the lab has tremendous value in creating repeatable tests, real-world testing is the ultimate validation. Ford Performance conducts extensive vehicle testing for potholes and curb strikes, as well as durability testing to make sure the wheels meet OEM standards.

The highlight of vehicle validation is the Ford Performance track durability procedure that aims to test the entire vehicle at its handling limit on a road course for a customer-correlated life of recreational track days. The carbon-fiber wheels must not only withstand the test, but show no degradation in dynamic performance at the end. This testing goes above and beyond typical passenger car validation and aims to ensure performance enthusiasts take delivery of a highly capable vehicle that remains so throughout its life.

Configure your own dream Ford GT at www.FordGT.com.

Sources: Ford Motor Co., Ford Performance, Carbon Revolution

Published May 2016

Rate this article

View our terms of use and privacy policy